Difference between revisions of "Magnet refills"

From Nuclear Physics Group Documentation Pages

Jump to navigationJump to search| Line 16: | Line 16: | ||

## Regularly check this location for leaks: It's the primary failure point. | ## Regularly check this location for leaks: It's the primary failure point. | ||

## We have a quick connect “Christmas Tree” that comes with the source dewar that should be used. If the Christmas Tree o-ring is broken, a thick o-ring between the dewar and the transfer line quick connect can suffice, as long as there is enough Teflon tape holding it in place. | ## We have a quick connect “Christmas Tree” that comes with the source dewar that should be used. If the Christmas Tree o-ring is broken, a thick o-ring between the dewar and the transfer line quick connect can suffice, as long as there is enough Teflon tape holding it in place. | ||

| − | ## Put a heat strap around the Christmas Tree on the source dewar. Make sure to monitor this temperature with a thermocouple to make sure it’s not | + | ## Put a heat strap around the Christmas Tree on the source dewar. Make sure to monitor this temperature with a thermocouple to make sure it’s not above 25% power. |

# Hook up dry helium line to source dewar for over pressuring. Do not open this line yet, we'll only need it after the transfer line cools. Make sure that the set output pressure is no higher than 5psi. Aim for 2.5 psi. | # Hook up dry helium line to source dewar for over pressuring. Do not open this line yet, we'll only need it after the transfer line cools. Make sure that the set output pressure is no higher than 5psi. Aim for 2.5 psi. | ||

# If filling the blue AMI dewar in preparation to use the evaporation fridge, make sure the blue-dewar-to-fridge transfer line is already installed. Make sure bypass and heat exchanger valves are all the way closed. The separator pump should also be off and the line to it closed. | # If filling the blue AMI dewar in preparation to use the evaporation fridge, make sure the blue-dewar-to-fridge transfer line is already installed. Make sure bypass and heat exchanger valves are all the way closed. The separator pump should also be off and the line to it closed. | ||

Revision as of 17:47, 17 August 2020

This is part of Shift Workers Documentation.

Notes:

- Always make sure there is a pop-off valve or similar fail-safe wherever there is cryogen! Do not turn the dewar into a pressure bomb.

- LHe fills should only be done when the solenoid temperature is less than 100K. If the temp has risen above 100K, stop and repeat the liquid nitrogen precool procedure.

- If the LHe fill is interrupted for any reason, stop the flow of dry helium gas.

- If helium is coming out anywhere except the far end of the transfer line, STOP! Think about where there are leaks and fix them before going forward. Every liter of helium gas coming out the top costs ~10¢ and fast plumes can release 10s to 100s of liters per second.

- Usually avoid using the heater on the silver dewar to build pressure. Always try to use the dry gas helium instead. It is far more efficient and doesn't waste liquid helium.

- This is a 2 person job. Do not attempt to do this alone unless you have >5 years of experience handling liquid helium and have already gone through a dry-run on your own. If you have any hesitation what-so-ever, STOP!

LHe Transfer Procedure

- Clean off lab table to lay out materials needed during cool-down, and clear work area inside the 5 Gauss line.

- Prepare all materials, including transfer lines, all extensions, quick connectors and quick connector Christmas Tree, o-rings, Teflon tape, cryo gloves, and face mask.

- Make sure all o-rings are good and there's good vacuum in the transfer line.

- Install quick connectors on the top of the source dewar, making sure there is an o-ring at every single joint along the way.

- Regularly check this location for leaks: It's the primary failure point.

- We have a quick connect “Christmas Tree” that comes with the source dewar that should be used. If the Christmas Tree o-ring is broken, a thick o-ring between the dewar and the transfer line quick connect can suffice, as long as there is enough Teflon tape holding it in place.

- Put a heat strap around the Christmas Tree on the source dewar. Make sure to monitor this temperature with a thermocouple to make sure it’s not above 25% power.

- Hook up dry helium line to source dewar for over pressuring. Do not open this line yet, we'll only need it after the transfer line cools. Make sure that the set output pressure is no higher than 5psi. Aim for 2.5 psi.

- If filling the blue AMI dewar in preparation to use the evaporation fridge, make sure the blue-dewar-to-fridge transfer line is already installed. Make sure bypass and heat exchanger valves are all the way closed. The separator pump should also be off and the line to it closed.

- Make sure the thick extension is on the source-side transfer line.

- Set up ladder(s) and put on cryo safety gear.

- Open source dewar top valve and close source dewar valve to the pop-off. Make sure that there’s always at least one opening for pressure to escape during this process.

- Measure and record the source dewar liquid helium level.

- Slowly insert thick end into source dewar until large white plumes come out the far end. It will be accompanied by a change in sound as it goes from gas to liquid going through the transfer line. You do not need to over-pressure the source dewar at this point, the heat of the transfer line alone will build enough pressure to create flow for a while.

- Once you get the white plumes and sound change, insert transfer line thin end into target dewar. Make sure the extension is not on, and that the brass thread protector is on.

- Once the transfer line thin end is in the target dewar, the target pop-offs should open. Take them off entirely at this point to avoid freezing them, as the filling process will create enough over-pressure to avoid atmosphere contamination.

- Turn on LHe level monitor to ‘Update’ read-out and pay attention to how the fill level changes over time. When LHe level slows, slowly pull up the line in the target dewar. The goal is to keep the end of the line just above the liquid level in the target dewar. Use the level monitor to guide roughly how high you pull it up, a few inches at a time. When the LHe level stops filling entirely, it’s time to begin over-pressuring the source dewar with dry gas helium. ‘b0b0’ indicates that the sensor is on Burn Out Protection mode. This is ok for short periods of time, but should not be left on for long periods of time.

- Have one person stationed near the dry helium gas line and another to work the source dewar and monitor the LHe level monitor.

- The gas line person should open the dry helium gas valve, aiming to keep the pressure at ~2.5psi. It should never go above 5psi while both ends are open. If the LHe fill is interrupted for any reason, shut off the flow of helium gas immediately.

- The source dewar person should open the dry gas line valve on their end, and then keep a close eye on the liquid level monitor.

- Once the desired level has been reached, turn off the dry gas line valves and open the source dewar’s line to the pop-off valve.

- Set the liquid helium level monitor from ‘Update’ to ‘Sample’. This stops continuous readings to one ever user-set amount of time to lower liquid helium losses that occur when the sensor is active.

- Reinstall the target dewar’s pop-off valves.

- Remove the transfer line from the target dewar first, followed immediately by removing it from the source dewar. It’s not uncommon for the quick-connects to become frozen to the lines at this point. If that happens, remove the transfer line with the quick-connects stuck to it and then slowly warm the stuck quick-connects with the heat gun until they slide easily, then rapidly remove them.

- After making sure you already opened the source dewar’s pop-off line, close the top valve on the source dewar.

- Reinstall the brass plug on the target dewar.

- Wait a few minutes for everything to stabilize, then record liquid level and resistance and temperature readings from AB.M1, AB.M2, AB.M3, AB.M4, and AB.M5.

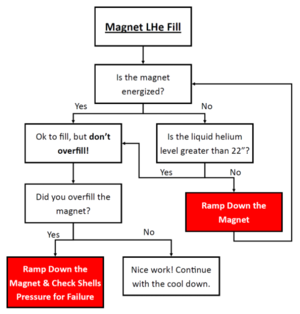

The procedure for filling the magnet with liquid helium is outlined in the 'Transferring Liquid Helium' section of the Cool-Down Procedures document found at https://docs.google.com/document/d/1ecbCTTtgoKBhofpUS1OsZVxOxAfA9XxAiUHVvF13A3o/edit#heading=h.c3x3myzfwqkv